#6 - Application - The Gun

Tuesday Tech Tip | | Written by: DBNZ Coatings

This article is part 1 of a series. You can read part 2 "The Applicator" here.

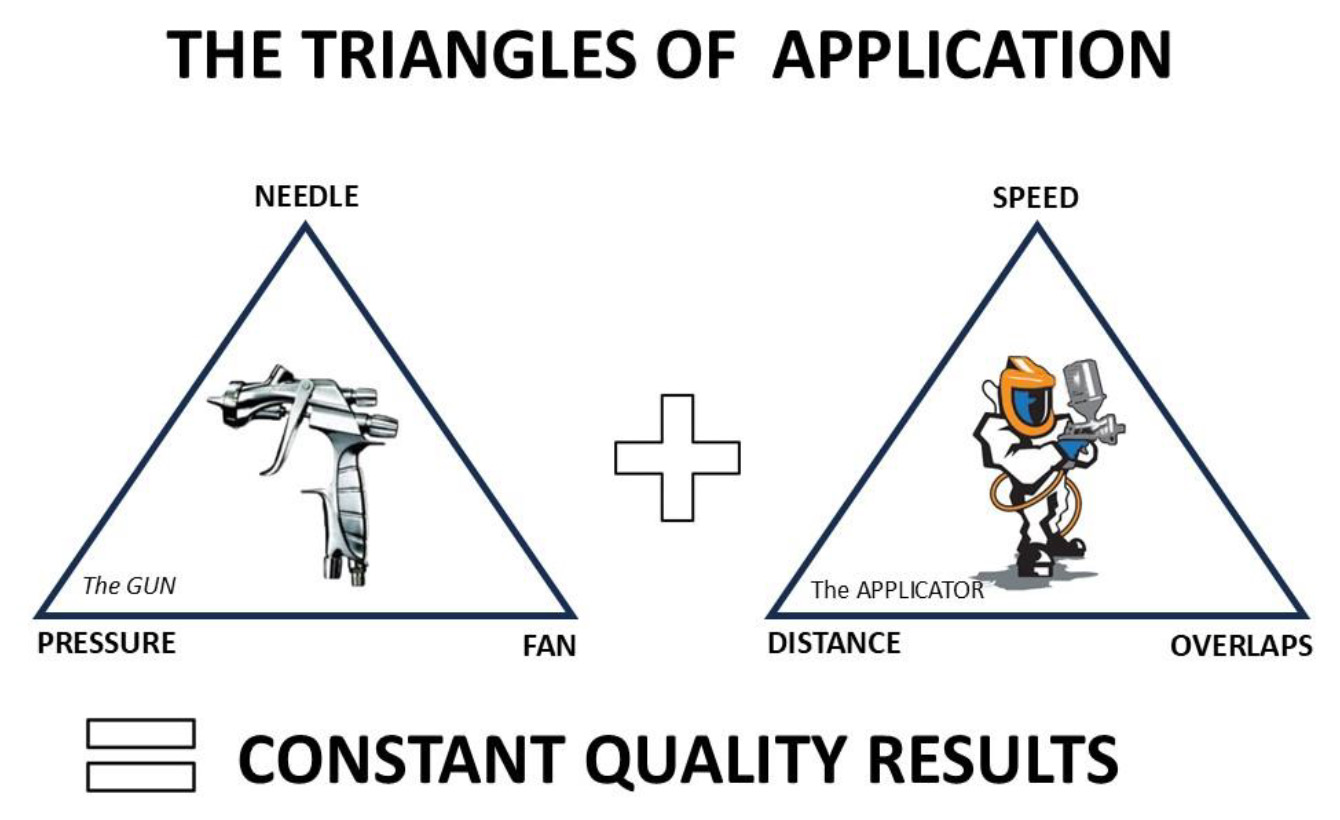

Application is key for consistent quality results in Automotive or any other spray coatings application using traditional compliant equipment.

A cornerstone for achieving the desired result is ensuring both the application equipment and the applicators physical application of the product is (as much as possible) the same every time the spraygun is picked up.

The information presented on here is to outline the basic fundamentals to set any applicator (who may not be aware) of the importance of gun setup and application.

As in any change of technique or the learning of a new way of doing something, the key is Practice, Practice, Practice.

Gun Setup

Needle:

The setting or position of the needle plays a huge part in regulating the amount of paint that leaves the spraygun nozzle and ends up on the substrate. Too much (the needle wound out wide open) can result in too much wet product applied, which on a vertical surface once gravity takes over can cause “runs and sags”

Due to the differences of guns from different manufactures the needle setting can vary from one gun to the next, however as a guide, e.g. an Iwata 1.3 topcoat gun, an initial needle setting (as a starting point) could be 3.25 turns out from the needles fully wound in position.

From this point you may find you may need to either open the needle up slightly, or wind it in slightly (to match you own physical application). Once you find the “Sweet Spot” that then becomes your setting.

Air Pressure Inlet:

Just as important is the inlet air pressure, always use a gauge (manometer) so you can see just how much air pressure is entering the gun. Make sure the guns own air adjustment valve is in the fully open position.

Modern compliant guns typically run at an inlet pressure of 1.8 - 2 Bar.

Fan Adjustment:

Typically wind the fan adjustment fully open, then wind it in 1 full turn (this just takes the extreme edge off the fan).

Combining the Needle, Air Pressure and Fan settings to find the best setting for you will go along way to improve the consistent quality of the paint jobs you produce.

Part two will focus on physical application

Download our recommended gun setup

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #6Size: 352KB | File Format: .pdf