#10 - Filtration & Breathable Airlines

Tuesday Tech Tip | | Written by: DBNZ Coatings

Filtration - Breathable Air

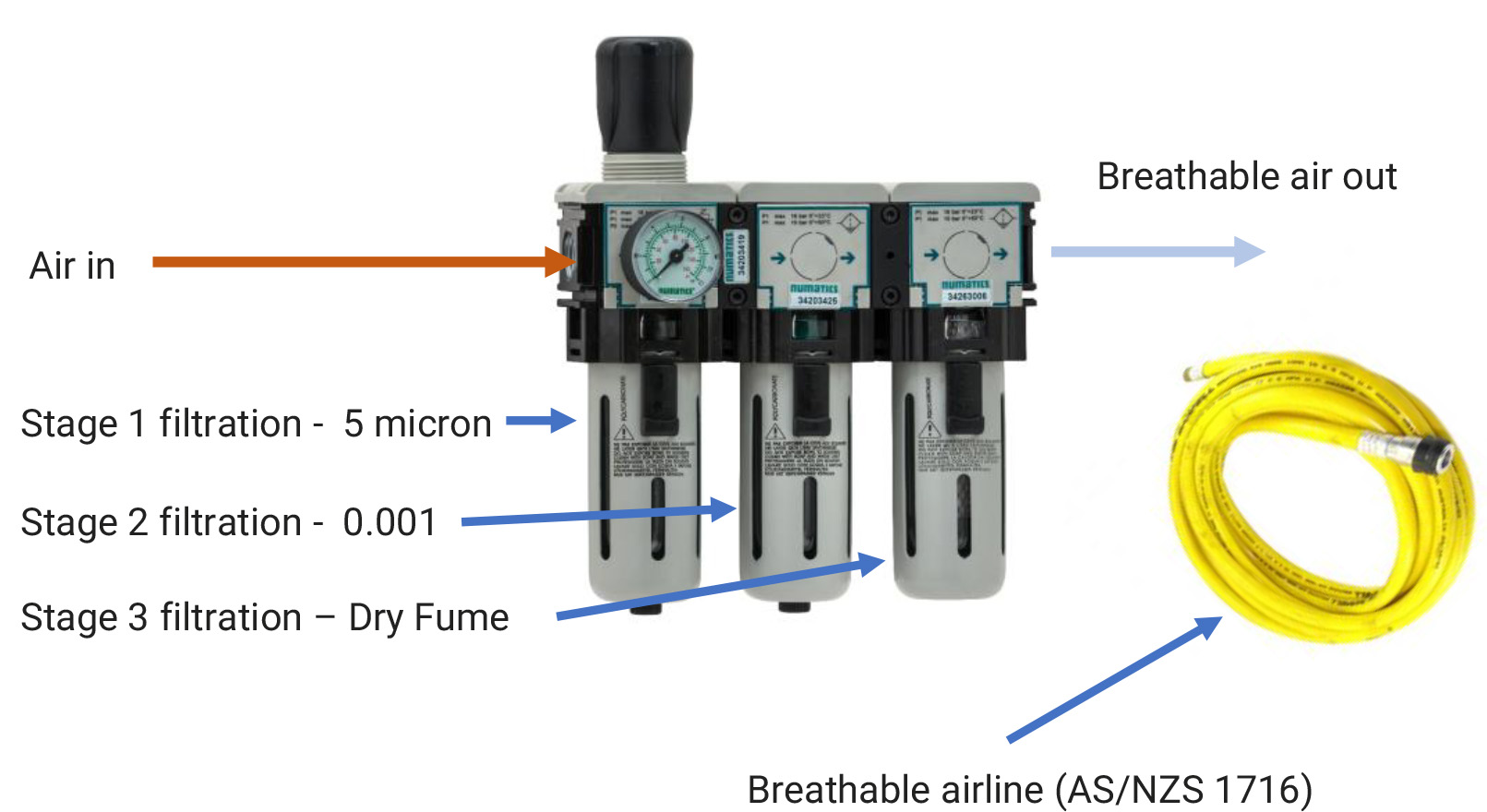

For compressor-supplied air to become safe to breathe it must go through at least 3 stages of filtration.

- Water trap, this has a 5-micron filter which will remove water and moisture and large particulates from the incoming “dirty air”.

(note: a water trap will not remove oil) - Coalescent (oil removing filter) removes oil and tiny particulates down to 0.001 microns. From this point only dry fume will remain.

- Charcoal filter removes the remaining dry fume.

(note: these charcoal filters are not designed to remove particulates)

Breathable - Airline

Breathable airlines need to meet the AUS/NZS 1716 Standard.

These airlines have a hospital grade inner liner which the clean air passes through providing a clean delivery system of air to the airfed mask.

These airlines are usually coloured yellow and have the AUS/NZS 1716 standard marked on the side.

Rubber airlines release dry fume within the inner lining, they can also crack and crumble on the inside over time sending even more fume and particulates down to the operator's mask.

Note: Operator air-fed belt filters are designed to stop dry fume only, not particulates.

Final Thoughts

Your Health is everything, without it you have nothing. We need to ensure we look after OWN health every day.

Small things you can do every day can protect your long-term health in major ways.

- Always wear the correct respirator.

- Avoid as much as possible coming into direct skin contact with the chemicals we use (wear those gloves and spraysuit).

This tip was originally written for DBNZ Coatings and has been re-posted with permission.

Download Tech Tip #10Size: 266KB | File Format: .pdf